My company, Clarify Health, commissioned me to build a LEGO sculpture to measure our progress toward our two-year goals. The concept was to build levels upward until we reached 100% of our three company goals. The hope was it would get everyone more excited about reaching our goals than seeing a PowerPoint slide every month. The finished towers stand more than six feet tall and use about 12,000 bricks.

I drew inspiration from a Canadian brick artist, Raymond Girard. His creations are architecturally simple but his use of color is sophisticated, which results in surprising, elegant outcomes.

I started the simple way – by building! The biggest challenge would be making three separate towers interconnected and sturdy. The towers would be placed in the office, so they had to be sturdy enough not to fall over if someone bumped into them. My approach was to have the three towers sloping inward as they grew and connect them with large joint pieces to form internal vertebrae.

After I had perfected the connection mechanisms and felt good about the structural integrity, I turned to digital building in Stud.io. This allowed me to work out some remaining design details and tweak the color choices. I discovered that the cost of bricks in the colors I wanted was way too high because the price of LEGO elements is based on scarcity. After locking in the final details and colors, I ordered bricks from about 75 stores worldwide. Getting lots of packages every day for a couple of weeks was fun! Here’s my LEGO studio at the time, with freshly arrived packages:

I ordered used bricks to save money, but it was a dumb idea because some vendors sent dirty bricks, especially the white ones that had to be washed. I threw them in the washing machine in clothes bags on a delicate cycle and then dried them on the floor. It was annoying and kind of satisfying.

The building was fast and fun. The goal was to build up to the level of our goals that we had already reached, about one-third the height of the towers. We would build the rest in our office over the next two years.

My cat Yolo was on point for frequent durability inspections. The interconnected joints proved strong enough to lock the towers in place and pass inspection.

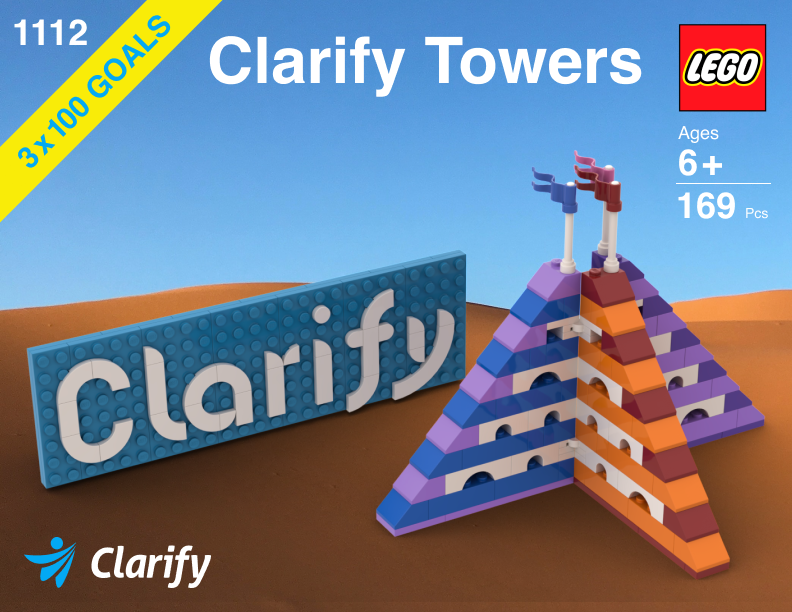

Meanwhile, our head of HR asked if we could do something for all the remote workers in the US and Canada. What about a small version of the LEGO towers? She approved the idea and I set about designing the small versions and ordering enough bricks for 140 sets.

Here’s what it looks like to sort a ton of bricks into sets and the crazy printed notes I used to keep track of things. The tiny pieces were the worst.

We also let everyone at the company choose a LEGO avatar and sent it to them with their set. Each set came with detailed building instructions, just like a real LEGO set.

I brought the towers into the office and had a big party to celebrate the company’s founding day. Remote workers got their kits and built them. Team members in San Francisco also got their minifigures and put them all over the towers.

Over the next two years, we built the towers higher and higher. The blue tower reached its full height within a year and the orange tower reached about 75%.

At the two-year mark, my company decided to retire the goals and set some new ones. I thought it would be fitting to have the company’s two founders destroy the towers in epic fashion, so we had an all-hands meeting and they demolished the towers with Nerf bats.